The small revolution of the eco-friendly leather jackets

The leather process required to make a jacket takes three months and thousand litres of water and chemicals. Spanish company La Doma is well aware because eight generations of the same family have been tanning leather through a process that has not changed a bit. Now, with the EEA Grants help, they are developing a prototype which will revolutionise the sector.

The leather process required to make a jacket takes three months and thousand litres of water and chemicals. Spanish company La Doma is well aware because eight generations of the same family have been tanning leather through a process that has not changed a bit. Now, with the EEA Grants help, they are developing a prototype which will revolutionise the sector.

09.07.2014

Juan Colomer has all his life dedicated to the tanning company La Doma, located in Centelles, Barcelona. Before him, his father and his grandfather and his great-grandfather, and now with him, his sons, the eighth generation of this long family tradition business. But times have really changed. 15 years ago there were over 40 companies producing lambskin in Spain, nowadays there are only two. The reason? The fierce competition from China and India which have much lower prices due to the low salaries and their carelessness about environment. For that reason, La Doma decided to fill a high-quality niche market –the jackets and coats in the world most luxurious shops are made with the leather from this small village- and to invest in R&D, in their opinion, “the only way to survive”.

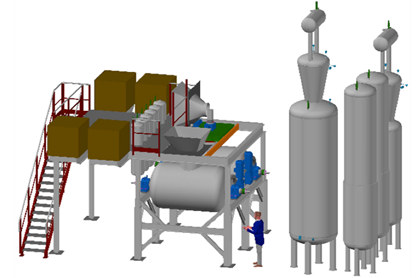

Tanning is a very labour-intensive industry and a considerable amount of water is wasted. So, La Doma is developing a prototype plant which will use Supercritical CO2 –CO2 under heightened pressure and temperature- in all the tannery process. The aim is to reduce the costs, to increase the quality and to minimize the environmental impact. For that reason, this is one of the approved projects in the first Open Call within the EEA Grants Environment and Climate Change Programme, operated by CDTI. “This funds are a great opportunity for those companies which need to invest in new projects, they are the R&D lungs”, highlights Juan Colomer junior.

The project will be carried out by 6 activities (engineering design, construction of the prototype, Assembly and commissioning, process development, development of chemical products and intellectual property). Tanning requires lots of water in order to dissolve and extract salt and other impurities from the skins. This project aims to replace water for compressed carbon dioxide which is not toxic, not harmful, non flammable and happens to be a secondary product, with a need to be used up. Therefore, it would be eco friendly and would improve the production efficiency and reduce the costs and the final price improving also the quality.

The project will be carried out by 6 activities (engineering design, construction of the prototype, Assembly and commissioning, process development, development of chemical products and intellectual property). Tanning requires lots of water in order to dissolve and extract salt and other impurities from the skins. This project aims to replace water for compressed carbon dioxide which is not toxic, not harmful, non flammable and happens to be a secondary product, with a need to be used up. Therefore, it would be eco friendly and would improve the production efficiency and reduce the costs and the final price improving also the quality.

The new and innovative process could have positive effects on the Norwegian and Icelandic economies. Norway has over 2,3 million lambs and goats but there is not a well-developed tanning industry because the skin is of low quality. La Doma developing project would achieve more compact leather and with higher quality that will help this two countries to develop their leather sector. Currently, Icelandic lambskin represent 10% of La Doma production, through Saudskinn.

La Doma board are aware that what they are trying to achieve is quite challenging. Other companies have tried and failed, but this Spanish family has something different: the moral duty to hand over La Doma reins to the next generation. And this will only be possible transforming a nineteenth century company into a twenty-first century one.